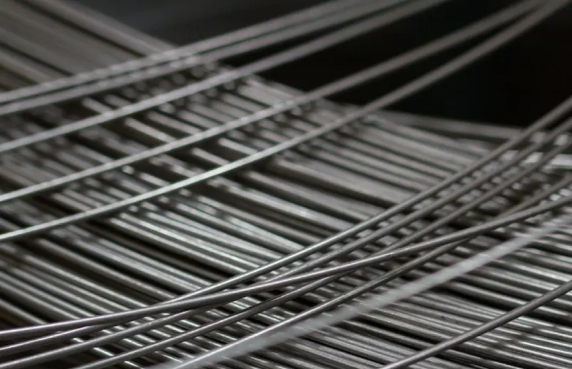

Safety lock wire is a durable, corrosion-resistant wire designed to secure fasteners, bolts and other hardware in place. Sunset Wire delivers top-quality wire that prevents loosening when it matters most.

Due to its strength and corrosion resistance, safety lock wire is used in all types of industries for critical applications:

Sunset Wire can manufacture safety lock wire in any diameter from .0150 – .0620 inches. Common sizes include:

Sunset Wire stocks a large inventory of safety lock wire to ensure you get it fast. Get your wire in 1 lb cans, 1 lb spools or 5 lb spools. Other spool sizes are available upon request.

Sunset Wire is proud to supply various safety lock wire alloys and meet all specifications.

Do you need wire specifications compliant with the DFARS special metals clause? We can help. Please specify DFARS compliance when requesting either a quote or an order.

Why Choose Sunset Wire?

Sunset Wire provides domestically drawn wire in various diameters, lengths and packages. Get your safety lock wire delivered anywhere in the US thanks to our large inventory and dedicated supply chain management capabilities.

Wire drawn and delivered to meet your timelines

We draw, grind, cut and package AS9100-certified stainless steel and nickel alloy wire for a wide variety of applications. With available inventory and the ability to meet a wide range of specifications, our lead times are typically 1-2 weeks.

Safety lock wire is a type of wire used to secure fasteners, bolts and other components in place to prevent them from loosening due to vibration or other operational forces. It’s commonly used in aerospace, automotive and industrial applications where safety and reliability are critical.

Safety lock wires are typically made from materials like stainless steel, Inconel or Monel. These materials offer excellent resistance to corrosion, heat and mechanical stress, ensuring durability in challenging environments.

Safety lock wire comes in various diameters to accommodate different applications. The appropriate size depends on the specific requirements of your project or industry standards.

The choice of size and material depends on factors such as operating environment, temperature and the load on the fastener. Consult the equipment manufacturer’s guidelines or industry standards like ASME or MIL-SPEC for specific recommendations.

No, safety lock wire is not reusable. Once it has been applied and removed, it should be discarded to ensure the integrity and reliability of the wiring in future applications.

You will need safety wire pliers (for twisting and securing the wire), wire cutters and possibly a pair of needle-nose pliers for tight spaces. Proper tools ensure the wire is installed correctly and securely.

Yes, safety lock wire must meet certain industry standards, such as those outlined in ASME, SAE or military specifications like MIL-DTL-83420. These standards ensure consistent performance and safety.

Yes, certain materials like Inconel and stainless steel are suitable for extreme temperature environments. Check the wire’s specifications to ensure it meets the temperature requirements of your application.

You can request a quote directly from Sunset Wire.

Sunset Wire is a domestic wire manufacturer that draws, grinds, cuts and packages AS9100-certified stainless steel and nickel alloy wire for various applications.

© 2025 Sunset Wire. All Rights Reserved. Designed & Developed by Altitude Marketing.