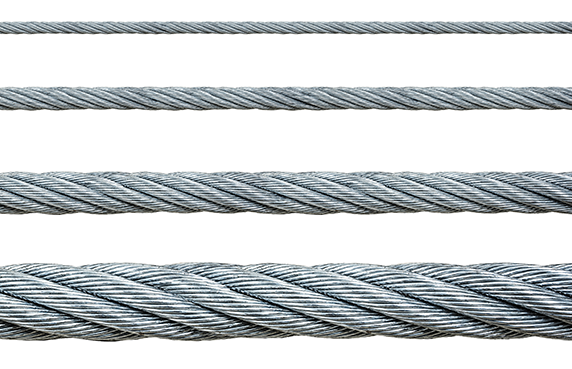

Stainless steel wire alloys are corrosion-resistant metal wires made from iron-based alloys containing chromium, nickel and other elements. Sunset Wire offers a wide variety of stainless steel alloys that are engineered for strength and corrosion resistance.

Choose from a range of stainless steel alloys for wire. If you don’t see a certain type of wire alloy listed here, contact us to discuss your needs. Other alloys are available on request.

Stainless steel alloys are known for their durability, resistance to rust and corrosion, high tensile strength and versatility. These wire alloys are commonly used in electrical wiring, wire mesh, springs, cables and fasteners.

Stainless steel 302 has a higher carbon content ranging from 0.15-0.30%, which provides increased strength but can slightly reduce its corrosion resistance compared to lower carbon grades. It’s used in the production of springs, fasteners, wire forms and certain medical devices and surgical instruments.

Stainless steel 302HQ is a specialized alloy that contains 3.00-4.00% copper, which lowers the rate of cold work hardening. It also includes a higher carbon content than grade 302, promoting better machinability and minimal tool wear.

Stainless steel 304 is a widely used austenitic stainless steel alloy known for its excellent corrosion resistance, versatility and ease of fabrication. It’s among the most commonly used stainless steel grades worldwide. Stainless steel 304 has a high carbon content with a 0.08% maximum. It’s often used in food processing, dairy and dyeing industry applications because of its corrosion resistance to atmospheric corrosion, organic chemicals and inorganic chemicals.

Stainless steel 304L is a low-carbon variation of the popular stainless steel 304 grade. Its carbon content is limited to a maximum of 0.03% to reduce the risk of sensitization during welding. Stainless steel 304L is typically used in food processing, chemical processing, pharmaceuticals and dairy equipment.

Stainless steel 305 has higher nickel content (10.50-13.00%), making it more suitable for applications that require extensive forming or deep-drawing processes. It also has the lowest rate of strain hardening in its class. Stainless steel 305 is commonly used in cold-headed bolts and screws, and its non-magnetic properties make it suitable for electrical applications.

Stainless steel 310 is a high-temperature-resistant austenitic stainless steel alloy. It is designed to withstand elevated temperatures and has excellent resistance to oxidation and scaling at high temperatures. Stainless steel 310 is used for high-temperature industrial furnaces, chemical processing equipment, petrochemical industry applications and cement plant components.

Stainless steel 316 is a popular austenitic stainless steel alloy that offers excellent corrosion resistance, high strength and good formability. It’s often referred to as marine-grade stainless steel due to its superior resistance to corrosion in marine environments where exposure to saltwater and harsh conditions is common.

Stainless steel 316L is a low-carbon austenitic alloy with 0.03% maximum carbon. It’s proven to minimize sensitization during welding. Stainless steel 316L is ideal for applications requiring higher machining speeds and lower cycle times. This includes marine, chemical processing, pharmaceuticals, medical devices and architectural applications.

Stainless steel 317 is a high-alloy austenitic stainless steel grade that offers enhanced corrosion resistance. It’s specifically designed for use in highly corrosive environments, such as chemical processing, pulp and paper industries and marine applications.

Stainless steel 317L is a low-carbon, austenitic stainless steel grade. It offers excellent strength, formability and toughness, making it a reliable material for challenging applications that require resistance to corrosion and high temperatures.

Stainless steel 321 is an austenitic stainless steel alloy that is stabilized with titanium. It’s designed to provide improved resistance to intergranular corrosion and high-temperature environments. Stainless steel 321 can be used in various aircraft, automotive and chemical processing applications.

Stainless steel 330, also known as UNS N08330 or Alloy 330, is an austenitic stainless steel alloy that offers excellent high-temperature strength and resistance to oxidation and carburization. It can withstand extreme heat and thermal cycling conditions. Stainless steel 330 is typically used in aerospace, food processing, petrochemical, petroleum and high-temperature applications.

Stainless steel 347 is an austenitic stainless steel alloy that’s stabilized with columbium (niobium). The columbium content provides improved resistance to intergranular corrosion, particularly in high-temperature environments. It’s utilized for applications in the aircraft, automotive and chemical processing industries.

Stainless steel 410 is a martensitic stainless steel alloy that contains 11.5-13.5% chromium, which provides its corrosion resistance and hardening properties. It’s commonly used to produce cutlery and kitchen utensils, bolts, nuts, fasteners, pump and valve parts, shafts, gears and steam and gas turbine blades.

Stainless steel 416 contains higher sulfur content, which enhances its machinability but reduces its overall corrosion resistance compared to other stainless steel grades. One of its primary advantages is its excellent machinability, making it easier to cut, drill and machine compared to other stainless steels. It’s widely used in various machine parts and certain firearm components.

Stainless steel 430 contains 16.00-18.00% chromium, which provides its corrosion resistance, but it has lower nickel content compared to austenitic stainless steel. It’s often more affordable than other stainless steel grades, and it’s commonly used in kitchen appliances, automotive trim and molding and indoor architectural components.

Stainless steel 17-4PH is a martensitic precipitation-hardening stainless steel. It’s a versatile and widely used grade of stainless steel known for its high strength, excellent corrosion resistance and unique ability to be hardened through heat treatment. Stainless steel 17-4PH can be found in aerospace, petrochemical, marine and medical applications. Designers and engineers can heat treat stainless steel 17-4 to various strength levels while retaining corrosion resistance to meet specific application requirements.

Stainless steel 17-7PH is a semi-austenitic precipitation-hardening stainless steel. It achieves its high strength through a process of solution annealing followed by aging. Common applications for stainless steel 17-7PH include aerospace components, springs, diaphragms and other automotive components.

Stainless steel wire alloys are used in various industries, including:

Sunset Wire can manufacture custom diameters for your project. Common sizes include:

Sunset Wire stocks a large inventory of stainless steel wire to ensure you get it fast. Get your wire in 1 lb cans, 1 lb spools or 5 lb spools. Other spool sizes are available upon request.

Why Choose Sunset Wire?

Sunset Wire provides domestically drawn wire in various diameters, lengths and packages. Get your stainless steel wire delivered anywhere in the US thanks to our large inventory and dedicated supply chain management capabilities.

Stainless steel wire alloys offer excellent corrosion resistance, high strength, heat resistance, durability and low maintenance.

Sunset Wire offers a wide range of stainless steel wire alloy types. Common grades include 304, 316, 430 and 17-7 PH, each offering different levels of corrosion resistance and strength.

Compared to carbon steel and aluminum, stainless steel provides superior corrosion resistance, higher tensile strength and better longevity in demanding environments.

Stainless steel wire alloys are used in aerospace, automotive, construction, medical, food processing, pharmaceuticals, marine, electronics, oil and gas, and filtration applications.

Yes, certain grades like 316L and 17-7 PH are biocompatible and commonly used in surgical instruments, orthodontics and medical implants.

Consulting with a Sunset Wire expert can help you select the best alloy based on environmental conditions, mechanical properties and industry standards.

You can request a quote directly from Sunset Wire.

Announcing our new wire calculator!