Cleaner Air for High-Altitude Comfort

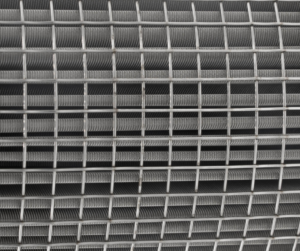

Flying at 30,000 feet means passengers and crew rely on recirculated air for hours at a time, making air quality a top priority. Modern aircraft, such as the Boeing 737 MAX or Airbus A320neo, operate with advanced environmental control systems to improve comfort, but this also heightens the need for robust filtration. GD’s industrial wire mesh filters are designed to tackle a wide range of airborne threats, keeping the cabin environment clean and safe. Our solutions remove:

- Fuel residues and exhaust byproducts

- Dust, sand, and other fine particles

- Bacteria, viruses, and allergens

- Odors from cleaning chemicals, ozone, and personal care products

By filtering out these contaminants, GD’s wire mesh ensures a healthier in-flight experience, meeting the stringent demands of aerospace clients while enhancing passenger satisfaction on long-haul journeys.

Quieter Skies with Advanced Noise Control

Airplane noise isn’t just a nuisance—it’s a regulatory challenge and a key factor in passenger comfort. Airports worldwide enforce strict noise limits, and travelers expect a peaceful flight. GD’s wire mesh plays a vital role in reducing noise from two major sources: jet engines and airframe components.

Inside engine nacelles, our wire mesh panels are engineered with thousands of micro-perforations—typically around 0.04 inches in diameter. These tiny holes channel sound waves into a honeycomb core, absorbing noise rather than letting it bounce off solid surfaces. To optimize sound absorption, GD designs our mesh with precise acoustic impedance, measured in Rayl values. For aerospace applications, our wire mesh typically achieves Rayl values between 80 and 150 Rayls, ensuring effective noise dampening without compromising airflow. This range is ideal for absorbing low-frequency engine noise, which can otherwise travel long distances and disrupt communities near airports. This technology helps reduce jet engine noise by up to 10 decibels, making flights quieter for both passengers and those on the ground. Additionally, our wire mesh has been proven effective in reducing landing gear noise during takeoff and landing, a critical area for noise compliance. With GD’s solutions, aerospace manufacturers can meet regulations and elevate the flying experience.

Safeguarding Jet Engines from Fuel Contaminants

Jet engines are the heart of any aircraft, but they’re vulnerable to fuel contamination from sources like airport fuel systems, transfer trucks, or even the plane’s own tanks. Tiny particles—often smaller than 1 micron—can build up on filters, potentially leading to a bypass scenario where contaminated fuel reaches the engine to keep it running. While this prevents a shutdown, it risks long-term damage and costly repairs.

- Debris: Paint flakes, metal shavings, and gasket fragments.

- Rust and Sediments: Caused by aging fuel infrastructure or poor filtration at airports.

- Organic Buildup: Fungi, molds, and oily residues.

- Miscellaneous Particles: Silicates, salts, and other unidentified materials.

By incorporating our wire mesh as a last chance filter, GD helps aerospace manufacturers protect engines from damage, avoid premature overhauls, and save millions in maintenance costs, keeping fleets in the air longer.

Preventing FOD (Foreign Object Debris) Risks with Wire Mesh Filters

Foreign Object Debris (FOD) poses a serious threat to aircraft safety, especially during ground operations, takeoff, and landing. FOD can include anything from loose tools and bolts to runway gravel, birds, or even ice fragments—any of which can be ingested by jet engines or damage critical systems. The Federal Aviation Administration (FAA) estimates that FOD costs the aerospace industry over $4 billion annually in damages, delays, and repairs.

GD’s wire mesh solutions are engineered to act as FOD filters, providing an essential barrier in engine inlets, air intakes, and other vulnerable areas. Our industrial-grade wire mesh is designed with precise weave patterns to capture debris as small as 0.5 mm while maintaining optimal airflow to prevent performance loss. For example, in engine air intake systems, our FOD filters can reduce the risk of blade damage by up to 70%, ensuring engines operate safely and efficiently. By integrating GD’s wire mesh FOD filters, aerospace manufacturers can enhance safety protocols, minimize downtime, and protect their fleets from costly repairs caused by foreign object ingestion.

Shielding Against EMI and RFI with Wire Mesh

Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) are growing concerns in aerospace, where sensitive avionics systems must operate without disruption. EMI and RFI can stem from onboard electronics, external radio signals, or even lightning, potentially affecting navigation, communication, and control systems. GD’s wire mesh provides an effective solution for EMI/RFI shielding, ensuring the reliability of critical aircraft systems.

Our wire mesh acts as a conductive barrier, creating a Faraday cage effect that blocks or redirects electromagnetic waves. Typically made from high-conductivity materials like copper or stainless steel, GD’s mesh is designed with fine weaves—often with openings as small as 0.1 mm—to provide up to 60 dB of shielding effectiveness across a wide frequency range (from 100 MHz to 10 GHz). This level of protection is crucial for avionics bays, where our mesh is integrated into enclosures to safeguard equipment like flight control computers and radar systems. By using GD’s wire mesh for EMI/RFI shielding, aerospace manufacturers can ensure uninterrupted system performance, enhancing both safety and operational efficiency.

Lightning Strike Protection Wire Mesh

Lightning strikes are a significant risk for aircraft, with the FAA estimating that commercial planes are struck by lightning once or twice per year on average. These strikes can induce powerful electrical currents, potentially damaging composite materials and critical systems. GD’s wire mesh provides essential Lightning Strike Protection (LSP), channeling these currents safely to prevent structural damage.

Our LSP mesh, typically made from highly conductive materials like copper or aluminum, is embedded into the composite materials of aircraft structures, creating an effective Faraday cage. This conductive network disperses electrical energy across the aircraft’s surface, protecting sensitive components from surges. GD’s LSP mesh is used in key areas such as the fuselage, wings, and composite helicopter blades, as well as in other composite applications like wind turbines, where lightning risks are also prevalent. For example, our mesh can handle current densities up to 200 kA, meeting stringent aerospace standards for lightning protection. By integrating GD’s LSP mesh, manufacturers can enhance aircraft durability, reduce maintenance costs, and ensure safety during adverse weather conditions.

The GD Difference in Aerospace Wire Mesh

At Gerard Daniel, we understand the high stakes of aerospace manufacturing. Our industrial wire mesh solutions are designed to:

- Protect critical systems like engines, hydraulic units, and auxiliary power systems from contamination and FOD.

- Shield avionics from EMI/RFI and safeguard aircraft from lightning strikes.

- Reduce noise to meet regulatory standards and improve passenger comfort.

- Ensure clean cabin air for healthier, more enjoyable flights.

Elevate Your Aerospace Projects with Gerard Daniel

As a leader in B2B industrial wire mesh, Gerard Daniel (GD) combines global expertise with tailored solutions to meet the needs of aerospace manufacturers. Under Gerard Daniel Worldwide (GDW), we’re committed to delivering high-performance wire cloth/mesh that drives innovation and reliability in aviation. Whether you need standard filters or custom-engineered mesh for a specific application, GD is here to help.

Let’s take your aerospace projects to new heights. Reach out today or visit Gerard Daniel to explore how our wire mesh can enhance your systems’ safety, efficiency, and performance.